+86 18153589066

+86 18153589066

- instant noodle processing machine

- Product brand:YUTONG

- Telephone:+86 18153589066

- Address: No. 300 Changjiang Road, Yantai City, China (Shandong) Pilot Free Trade Zone

-

Yutong characteristic service

Support non-standard customization and provide solutions

Support non-standard customization and provide solutions Improve after-sales service and provide guidance

Improve after-sales service and provide guidance

1. Classified by processing technology:

① Fried instant noodles: ② Non-fried instant noodles: ③ Fresh noodles:

2. Classification by surface type:

① Square instant noodles: ② Round instant noodles: ③ Hanging noodles: ④ Sheet:

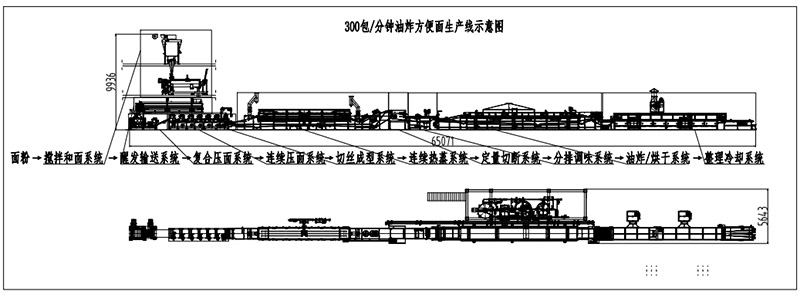

Second, instant noodle production line processing process

Salt water→flour→Mix and flour→Awakening delivery→Composite lamination→Continuous tablet→Cutting molding→Continuous steaming→Quantitative cut-off→Split seasoning→Frying/drying→Finishing cooling→package

Instant noodle production line processing technology flow

Three, instant noodle production line processing equipment parameters

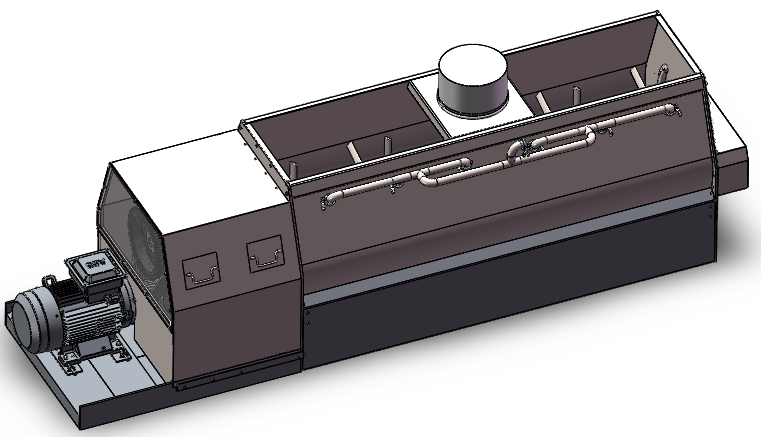

1. Mixing and noodles system:

Function description: It is used to mix flour with a certain proportion of salt water (1:0.34) and stir it into dough. The flour is added with salt water in proportion in a horizontal mixer equipped with a salt water supply system, and is mixed for 15 to 20 minutes to form dough, and then enters the dough conveyor.

Component equipment: rotary feeder, brine mixing tank, horizontal mixer, etc.

Technical parameters:

Rotary feeder: conveying capacity 75kg/min; Powder storage drum: 300kg/ set; Brine mixing tank: 1.5m³/ set;

Total system power: about 24kw;

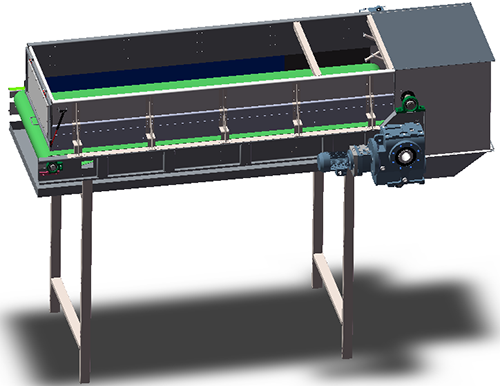

2, wake up conveying system:

Function description: It is used to wake up the dough. The dough is slowly transported through the dough conveyor for 10 to 15 minutes, fully awakened, and then enters the compounding machine.

Component equipment: dough conveyor, etc.

Technical parameters:

Total system power: about 3kw;

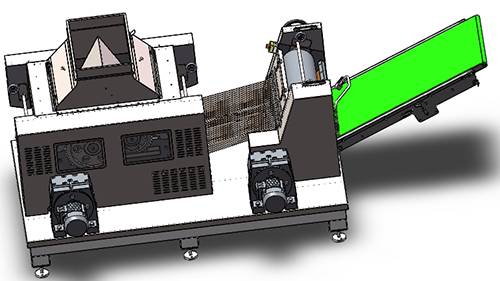

3, composite tablet system:

Function description: It is used to roll dough into dough through the composite machine, and then enter the calender in the order of the end.

Component equipment: composite machine, etc.

Technical parameters:

Total system power: about 10kw;

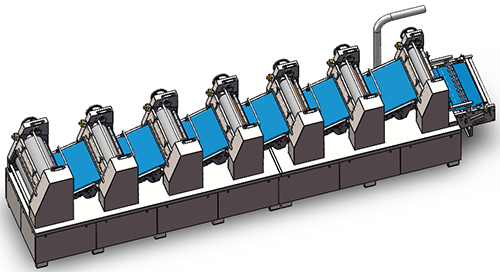

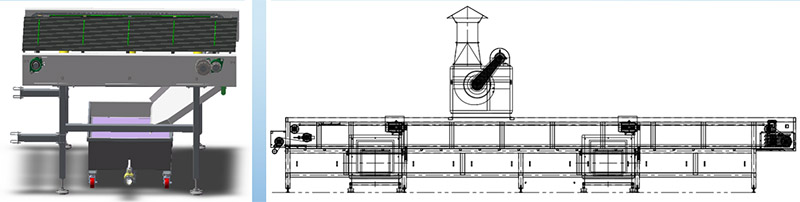

4, continuous sheet pressing system, cutting molding system:

Function description: The dough is successively entered into the press roller at all levels, the roll forms the required thickness of the surface, and finally through the cutting knife, cut into strips, and then into the multi-layer continuous steaming box.

Component equipment: calender, etc.

Technical parameters:

Total system power: about 33kw;

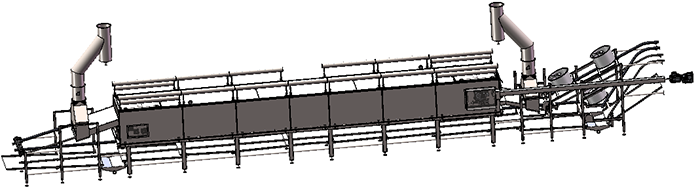

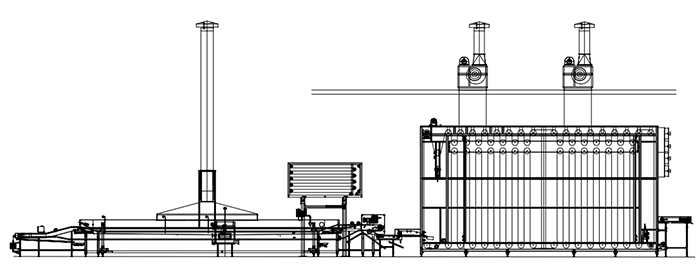

5, continuous steam system, quantitative cutting system:

Function description: Noodles are steamed for 120 ~ 200 seconds in a multi-layer continuous steaming box at a temperature of 95 ~ 105℃, and finally cut off quantitatively by a cutting machine, and then enter the seasoning machine.

Component equipment: multi-layer continuous steaming box, cutting machine, etc.

Technical parameters:

Total system power: about 5kw;

Steam consumption of multi-layer continuous steamer: about 400kg/1T surface

6. Seasoning system:

Function description: The noodles after quantitative cutting are sprayed or cooked for seasoning, and then enter the continuous frying machine.

Component equipment: seasoning machine, etc.

Technical parameters:

Total system power: about 3kw;

7. Frying/drying system:

The noodles are fried for 100 ~ 150 seconds in a continuous frying machine with hot oil at a temperature of 155 ~ 165 ° C (folded surface: 100 ~ 120 seconds, scattered surface: 100 ~ 150 seconds). Or the noodles are dried for 45 to 50 minutes in the continuous dryer through the hot air at a temperature of about 80 ° C, and finally enter the cooling machine through the finishing machine.

Component equipment: continuous frying machine, continuous dryer, etc.

Technical parameters:

Total system power: about 15kw;

Steam consumption of continuous frying machine: about 1300kg/1T surface

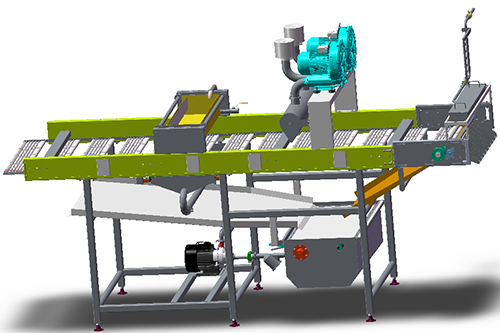

8. Finishing cooling system:

Function description: The cooling machine is equipped with a turbine chiller, which cools the noodles after frying or drying for 90 to 100 seconds.

Component equipment: finishing machine, cooling machine, etc.

Technical parameters:

Total system power: approx. 15kw

- Service hotline:+86 18153589066

Address: No. 300 Changjiang Road, Yantai City, China (Shandong) Pilot Free Trade Zone

Address: No. 300 Changjiang Road, Yantai City, China (Shandong) Pilot Free Trade Zone